Hello all. I am very new to this but it is all very cool to me. I ran into a problem and I am not sure how to troubleshoot it. I downloaded a simple pull string helicopter off thingiverse. After running through the slicer software, the estimated build time is 131 hours. Relative to it’s size this seems insane. If I “run the simulated build”, there are long holds on one of the interior walls. I am hesitant to just “try it” and see if the pauses are a software thing that does not translate to the hardware. I am not sure how to break it down from here. Any advice?

Link to the plans included

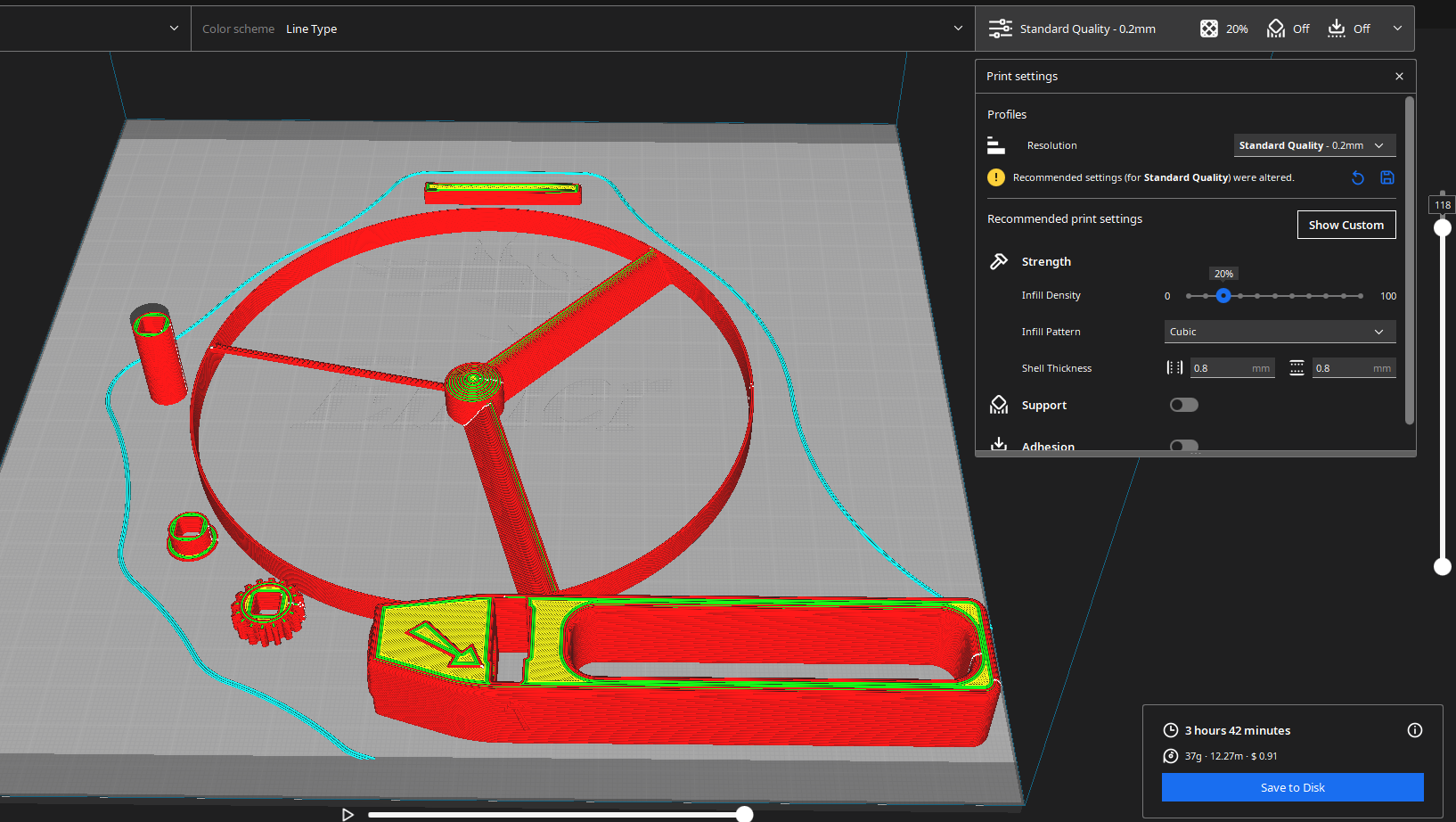

You definitely don’t need a layer height that low for something like this. Even still, you’ve got something set up weird because at a normal 0.2mm layer height it’s showing just under 4 hours to print everything but the pull rods (only because I’m too lazy to split the STL apart right now.) Try resetting your build settings or start a ‘new’ project.

When I switch to 0.2mm the time goes to 83 hours, so I assume there is still some error. What slicer do you use?

Don’t use Creality Slicer, it’s just an outdated renamed version of Cura. Download the most recent version of Cura here and your problems will most likely go away. https://ultimaker.com/software/ultimaker-cura/

As you said. I tried this and it fixed everything. Thank you

Thanks. Will try this.

Perry the helicopter?!

I suspect what’s getting you is minimum layer time. In a nutshell, extruding very hot plastic onto a layer that was very recently extruded can result in a runny mess. Minimum layer time is intended to address this.

That said 131 hours seems a bit intense.

What’s your layer height? How good is your cooling? If you crank your fan, you might be able to decrease minimum layer time.

Just to add on to this, if OP is printing this standing then it really should be laid on iits side, so that the hole in the handle is facing up & down, not sideways. Looking at this print that’s definitely how it should be printed. Vertical not only runs into layer time issues, but it’s a tall, thin object with loads of layer seams in the middle. It will be extremely weak. Lying down the layers run along the length of it, making it stronger. If the hole is sideways, then one side of the handle makes a giant bridge, which could fail the print entirely or need lots of supports.

I imagine the designer very intentionally made it to print on its side.

Oh and put the embossed arrow facing up, assuming the other side is flat.

Can you give us your basic info:

- Which printer

- Which slicer

- What kind of profile

- Which preset (if any)

- What filament is selecte

- did you change any settings

and just posta screenshot of the sliced model that the slicer should show you, makes it much easier to recognize trivial errors like wrong orientation.

Here is what I remember.

Creality ender 5 s1 Creality slicer High detail profile (Infill % 15, speed 100, nozzle temp 205, bed temp 60, z axis 0.1) PLA These were the default with no changes.

I am not sure what other parameters can be changed.

I will post a screenshot tonight. I did notice that 99% of the time is on the outer wall, this is where I noticed the pauses when I simulate the print.